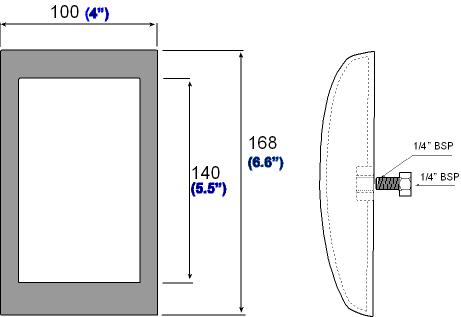

FLUIDIZATON PAD |

|

The Powtek A-15 Fluidization Pad It is one of the most simple and economical With its large contact surface and its round shape air is distributed more uniformely to the material inside the bin. Being made in of durable polymer |

HOW IT WORKS By adding air to the powder inside the silo’s cone the friction between the wall The number of pads to be used depends on the The operation cycle can be: |

|

| TECHNICAL SPECS | |

Pressure |

3 PSI |

Air consumption |

0.1 cfm at 3 PSI |

Weight |

1/2 lbs |

Housing |

Durable Polymer |

Contact surface |

100 sq cm - 15 sq inches |

Inlet air port size |

1/4" BSP |

In order to operate the fluidization

pads the follwing components

are needed: |

Time of opening should be long

enough to properly fluidize product

to achive best product outflow.

However it should not be too long

as it might add too much air and

reduce the specific weight of the material. |

|

Example: The installation is made from inside. |

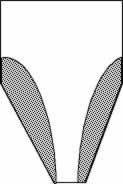

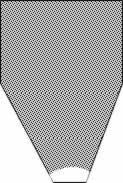

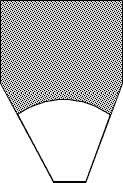

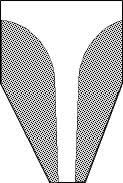

COMMON BIN PROBLEMS WITHOUT FLUIDIZATION |

|||

CLINGING |

BRIDGING |

ARCHING |

RATHOLING |

|

|

|

|