|

The Powtek U-2 Fluidization Nozzle is used to aid the flow of product out of bins and silos. It is fast and easy to install - just drill a hole, weld the bushing and insert the nozzle. With the Powtek Nozzle installation and maintenance are done from the outside. . |

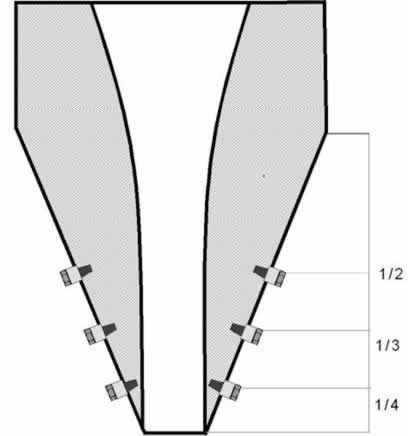

How it works By adding air to the powder inside the silo’s cone the friction between the wall and the product is reduced enhancing a more balanced material discharge. Since the entire body is made of carbon steel, it can be extracted and applied again as many times as necessary as opposed to other models on the market made of plastic that can only be cleaned once or twice. The number of nozzles to be used depends on the size of the cone. The operation cycle can be: |

LAYOUT- BOTTOM VIEW |

LAYOUT- SIDE VIEW |

|

|

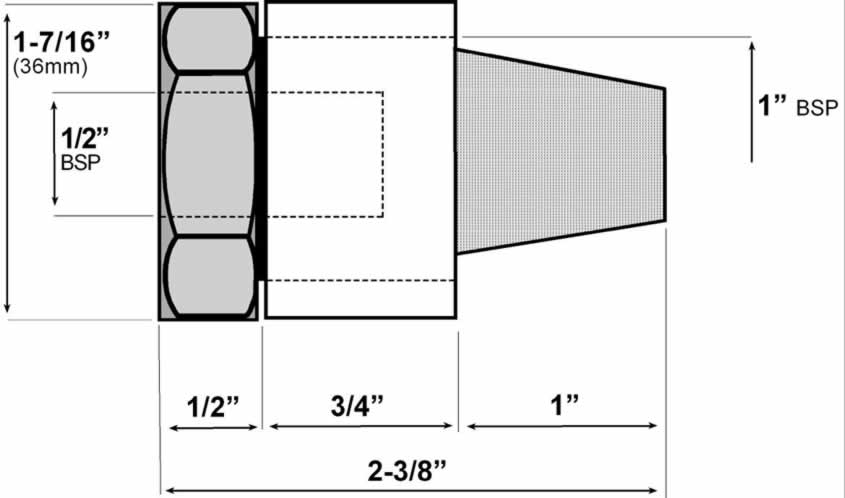

How to install 1. Drill a 1-7/16” diameter hole on bin’s cone.

|

DIMENSIONS |

|

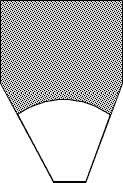

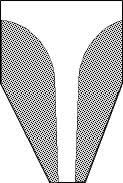

COMMON BIN PROBLEMS WITHOUT FLUIDIZATION |

|||

CLINGING |

BRIDGING |

ARCHING |

RATHOLING |

|

|

|

|

TECHNICAL SPECS. |

|

| Air Pressure : | 2 to 5 PSI |

| Air consumption : | 0.1 cfm at 5 PSI |

| Weight : | 10 Ounces |

| Housing : | Nickel Coated Carbon Steel |

| Bushing construction: | Carbon Steel |

| Exhaust port material : | Bronze alloy |

| Inlet port size : | 1/2" BSP |