In the world of turbine vibrators the GT Vibrator has been rated The vibrator life is unparalleled thanks to the housing precision machining |

|

|

| GT PERFORMANCE DATA | |||||||||

MODEL |

FREQUENCY |

FORCE OUTPUT |

AIR CONSUMPTION |

||||||

30 PSI |

60 PSI |

90 PSI |

30 PSI |

60 PSI |

90 PSI |

30 PSI |

60 PSI |

90 PSI |

|

vpm |

vpm |

vpm |

lbs |

lbs |

lbs |

cfm |

cfm |

cfm |

|

GT 4 |

14000 |

15000 |

16000 |

25 |

35 |

45 |

1.7 |

3 |

4 |

GT 6 |

11000 |

12000 |

13000 |

32 |

50 |

60 |

1.8 |

3.1 |

4.4 |

GT 8 |

35000 |

41000 |

45000 |

220 |

450 |

640 |

2 |

3 |

4 |

GT 10 |

27000 |

34000 |

37000 |

190 |

290 |

520 |

2 |

3 |

4 |

GT 10 S |

17000 |

23000 |

25000 |

140 |

300 |

440 |

2 |

3 |

4 |

GT 13 |

25000 |

29000 |

32000 |

310 |

530 |

830 |

4 |

7 |

10 |

GT 16 |

16500 |

21000 |

23000 |

290 |

450 |

700 |

4 |

7 |

10 |

GT 16 S |

11000 |

15000 |

17000 |

250 |

420 |

600 |

4 |

7 |

10 |

GT 20 |

16000 |

20000 |

23000 |

470 |

870 |

1200 |

6 |

12 |

16 |

GT 25 |

11500 |

16000 |

18000 |

450 |

780 |

1100 |

6 |

12 |

16 |

GT 25 S |

8000 |

11000 |

13000 |

500 |

800 |

1100 |

6 |

12 |

16 |

GT 30 |

12000 |

14000 |

16000 |

670 |

1100 |

1350 |

12 |

19 |

26 |

GT 36 |

7500 |

10000 |

13000 |

760 |

1150 |

1500 |

12 |

19 |

26 |

GT 36 S |

6000 |

8500 |

8000 |

4000 |

1400 |

1650 |

12 |

18 |

26 |

GT 40 |

7500 |

7500 |

9500 |

4300 |

1650 |

2200 |

15 |

24 |

34 |

GT 48 |

5500 |

7000 |

8500 |

4900 |

1700 |

2350 |

15 |

24 |

34 |

GT 48 S |

N.A. |

4500 |

6000 |

N.A. |

1650 |

2700 |

15 |

24 |

34 |

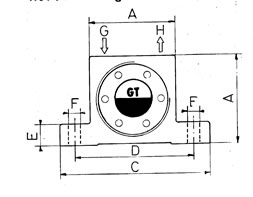

GT DESIGN

|

|

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TECHNICAL DATA | |

| Unbalance Weight : | Aluminium

Rotor with positive and negative unbalance (brass or heavy metal) |

| Lubrication : | not necessary |

| Air Supply : | 30 to 90 PS (2 to 6 bar ) |

| Air Type : | Clean, use of filter (40 µm) recommended |

| Body : | Aluminum, stove-enamelled yellow |

| End Caps : | Aluminum, black anodized, threaded |

| Max Temperature : | 250°F=120°C |

| Noise Level Range : | 60 to 75 dBA with silencer |

ADDITIONAL TECHNICAL INFORMATION

The vibrator body is made from an extruded aluminum alloy profile, and the threaded end plates are hard coated so that the vibrator can be used in the food and pharmaceutical industries. Air pressure inlets and exhaust ports have BSP thread (British Standard Pipe) but will accept US NPT ( National Pipe Thread) |

|

Due to its low noise level it may be used instead of all other vibrator types where there are low noise requirements. It can also be used wherever no lubricated air pressure is available . The Golden Turbine Vibrator can be placed in any position, but in order to increase its lifetime the vibrator should be operated, whenever possible, with the rotor axle horizontal so that the ball bearings do not get side pressure.Intermittent operation is not suggested since when air pressure is cut down, the rotor will continue running for about ten seconds. Thus, it should only be operated intermittently if the off time is more than 10-20 seconds. Lubrication is not required, but an air line filter should be used to prevent dirt from clogging the muffler. |

| Very often it is

better to run two smaller vibrators instead of a large one. The units should be placed opposite each other on the bin or hopper so the structure is not stressed too much at one single point. |

| Materials | ||

| Weight

of the product ((cone section only) in lbs. |

grain, corn, coffee dry powders, flours |

cement, concrete, sugar salt, chemicals |

| 100 | ||

| 200 | ||

| 400 | ||

| 600 | ||

| 1000 | ||

| 1600 | ||

| 2,000 | ||

| 3,000 | ||

| 4,000 | ||

| 6,000 | ||

| 10,000 | ||

| 15,000 | ||

| 20,000 | ||