|

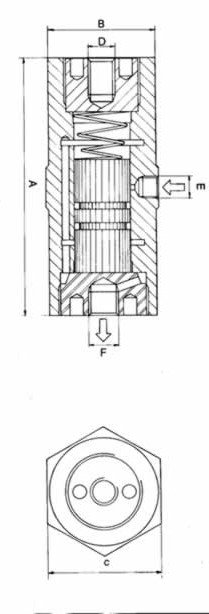

DESCRIPTION The FP and FPLF series pneumatic piston vibrators produce a linear vibration with adjustable amplitude and frequency. FP series needs a standard airline lubrication The frequency is controlled by adjusting the air pressure. |

| PERFORMANCE | ||||||||||

| MODEL | FREQUENCY | FORCE OUTPUT | AIR CONSUMPTION | NOISE | ||||||

| 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | ||

| vpm | vpm | vpm | lbs | lbs | lbs | cfm | cfm | cfm | dBA | |

| FP 12 S | 6200 | 7800 | 9300 | 6 | 10 | 16 | 0.03 | 0.26 | 0.88 | 47-61 |

| FP 12 M | 5000 | 6000 | 6700 | 7.7 | 13 | 18 | 0.02 | 0.14 | 0.67 | 57-61 |

| FP 12 L | 4000 | 4800 | 5400 | 8 | 14 | 19 | 0.04 | 0.11 | 0.71 | 58-60 |

| FPLF 12 M | 5000 | 6000 | 6700 | 7.7 | 13 | 18 | 0.02 | 0.14 | 0.67 | 57-61 |

| FP 18 S | 5000 | 6400 | 7700 | 13 | 28 | 40 | 0.18 | 0.16 | 2 | 62-71 |

| FP 18 M | 4000 | 5000 | 5900 | 14 | 30 | 42 | 0.14 | 1 | 1.84 | 61-67 |

| FP 18 L | 3100 | 4000 | 4600 | 15 | 34 | 46 | 0.18 | 1.81 | 1.62 | 61-68 |

| FPLF 18 M | 4000 | 5000 | 5900 | 14 | 30 | 42 | 0.14 | 1 | 1.84 | 61-67 |

| FP 25 S | 3600 | 4300 | 5500 | 28 | 61 | 94 | 0.46 | 1.91 | 3.3 | 70-73 |

| FP 25 M | 3000 | 3800 | 4200 | 32 | 82 | 113 | 0.81 | 1.76 | 3.07 | 71-74 |

| FP 25 L | 2400 | 3100 | 3700 | 42 | 88 | 134 | 0.64 | 2.19 | 3.28 | 72-75 |

| FPLF 25 M | 3000 | 3800 | 4200 | 32 | 82 | 113 | 0.81 | 1.76 | 3.07 | 71-74 |

| FP 35 S | 3800 | 4700 | 5800 | 66 | 150 | 234 | 0.81 | 3.56 | 5.72 | 72-75 |

| FP 35 M | 3000 | 4000 | 4600 | 56 | 175 | 243 | 0.85 | 2.93 | 4.98 | 73-75 |

| FP 35 L | 2400 | 3100 | 3600 | 63 | 153 | 240 | 1.34 | 3.14 | 4.77 | 73-75 |

| FPLF 35 M | 3000 | 4000 | 4600 | 56 | 175 | 243 | 0.85 | 2.93 | 4.98 | 73-75 |

| FP 50 M | 1800 | 2300 | 2700 | 110 | 220 | 360 | 1.7 | 3.5 | 6.6 | 72-78 |

| FP 60 M | 1900 | 2400 | 2700 | 140 | 315 | 489 | 3.1 | 5.6 | 9.4 | 72-78 |

| FP 95 M | 1800 | 2400 | 2800 | 340 | 590 | 962 | 5.9 | 11 | 15.6 | 75-80 |

FEATURES

The aluminum body is hard coated and it is corrosion resistant. |

The high power-to-weight ratio of the unit makes it particularly efficient for feeder pplications. |

Easy to install and designed to work continuously under the most demanding conditions. |

With proper muffler these units are very quiet and usually below 75 dBA. |

There is no paint to flake off. |

Explosion proof, light weight and compactness make these units ideal

for most applications. |

The FPLF, being lubrication free, discharges

no oil mist into the atmosphere. |

Estremely low air consumption |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

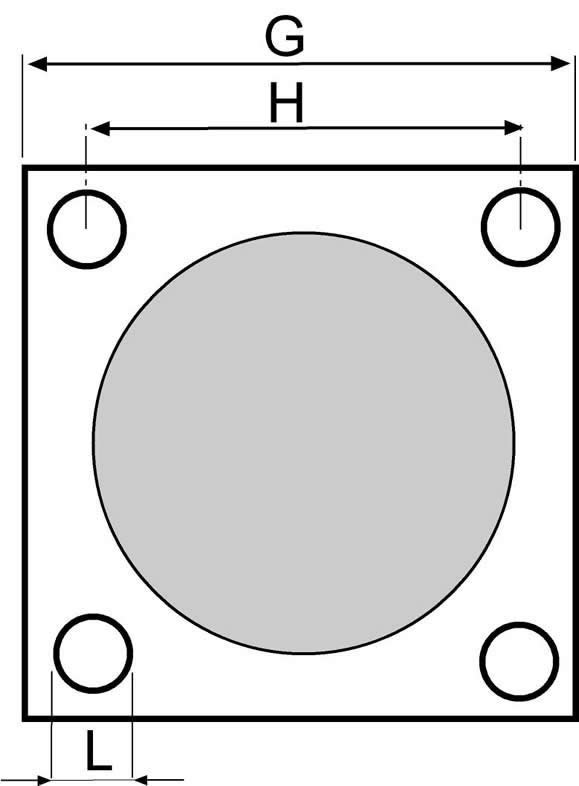

TECHNICAL DATA |

|

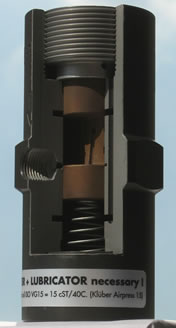

| Unbalance Weight: | Bronze Piston |

| Lubrication: | Necessary (Oil ISO VG5 = 5 cSt/40°C or distilled water) |

| Air Supply: | 30 to 90 PSI |

| Air Type: | Clean, 5 µm filter required |

| Body: | Aluminum, block anodized and teflonized |

| End Cap : | Aluminum socket with metric mounting thread plastic or aluminum end cap |

| Max Vibrator Temperature: | 250° F (=125° C) |

| Noise Level Range: | 57 to 74 dBA with muffler |

ADDITIONAL TECHNICAL INFORMATION

The

FP-series vibrators are non impacting so the piston does not hit the

socket, but rather stops on an air cushion formed

in the respective

chamber (socket or end cap side). The force/time curve is therefore

relatively sinusoidal without peaks.

This feature is excellent whenever

parts have to be moved.

The maximum ambient operating temperature is 50°C = 120°F

Piston

vibrators with aluminum end cap may be operated at higher temperatures,

but the vibration power will decrease due to increased leakage.

The noise level is extremely low, from 57 to 74 dBA.

The

FP-series piston vibrators are used mainly for feeding materials mounted

on chutes, spiral chutes and channels :

The FP-piston vibrator can be placed in any position.

An air line filter with five micron ( 5 µm ) is required to keep dirt from entering and blocking the piston.

A lubricator filled with oil (ISO VG5 = 5 cSt/40°C) or distilled water should be used to avoid abrasion.

Although

intermittent operation is possible without lubrication if the operation

factor is less than 20%,

we do strongly recommend that you always

lubricate.

Please

note that when mounted in upright position it will take up to two

seconds for the piston to move back to its end position

after the

air pressure is cut down because the piston has to move air out of

the housing with the help of the starter spring.

If the vibrator will

be operated intermittently, the starter spring should be turned to

the upper side so that gravity supports the spring.