|

DESCRIPTION The DAR Roller Vibrator offers an extremely |

| PERFORMANCE | |||||||||

| MODEL | FREQUENCY | FORCE OUTPUT | AIR CONSUMPTION | ||||||

| 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | 30 PSI | 60 PSI | 90 PSI | |

| vpm | vpm | vpm | lbs | lbs | lbs | cfm | cfm | cfm | |

DAR-2 |

36000 |

38000 |

38000 |

500 |

760 |

920 |

2.5 |

5 |

7 |

DAR-3 |

27000 |

32000 |

32000 |

612 |

920 |

1360 |

3.5 |

7 |

10 |

DAR-4 |

18000 |

22000 |

25000 |

530 |

1030 |

1500 |

4.2 |

9 |

13 |

DAR-5 |

9500 |

15000 |

16000 |

480 |

1120 |

1620 |

4.6 |

9.5 |

14 |

DAR-6 |

7800 |

10000 |

12000 |

980 |

1500 |

2300 |

6 |

11 |

16 |

DAR-7 |

8000 |

9800 |

11000 |

1300 |

2100 |

2700 |

6.4 |

12 |

17 |

. . |

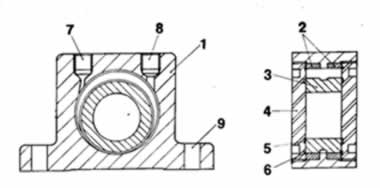

1. Extruded aluminum alloy body |

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

APPLICATIONSThe

DAR-series roller vibrators provide a new approach in compacting and

moving fine heavy materials.

|

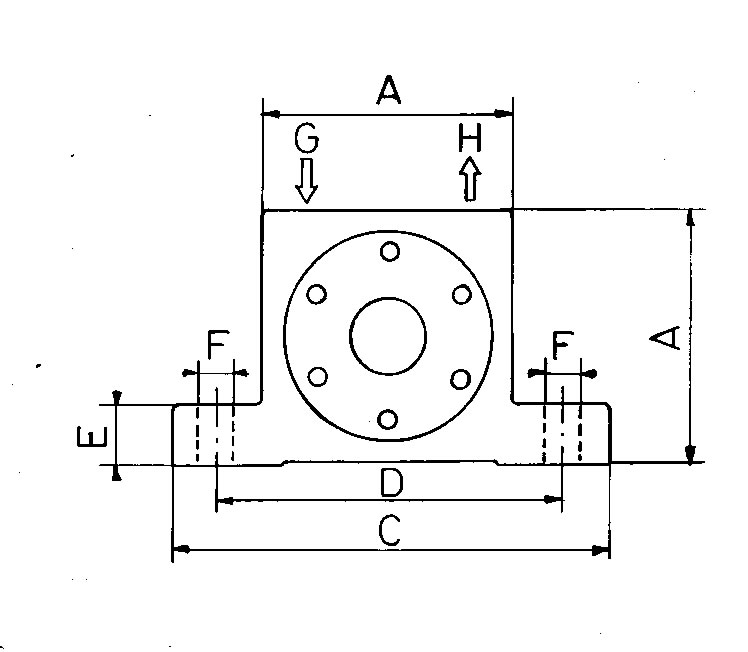

TECHNICAL DATA |

|

| Unbalance Weight: | Cast iron roller |

| Lubrication: | Necessary (Oil ISO VG5 = 5cSt/40°C) |

| Air Supply: | 30 to 90 PSI (2 to 6 bar) |

| Air Type: | Clean, use of filter (40µm) recommended |

| Body: | Aluminum, stove-enamelled orange |

| End Cap : | Bronze, threaded (Left and right hand) |

| Ambient Temperature: | 400°F(200°C) |

| Noise Level Range: | 75 to 100 dBA with muffler |

ADDITIONAL TECHNICAL INFORMATION

The

vibrator housing is machined from an aluminum alloy profile.

The

housing has two mounting holes.

The

air inlet port and the exhaust port are tapped with standard pipe

thread.

The pipe thread is BSP (British Standard Pipe) but will accept

US NPT( National Pipe Thread) .

For optimal performance, mufflers of sintered bronze should be used to improve exhausting.

The DAR indicates the heavy roller series and the number (2 to 7) is a running number.

The maximum ambient operating temperature is 200°C (400°F).

The noise level range is 75 to 100 dBA with silencers.

The

vibrator should be placed so that its rotative axle is horizontal

in order to avoid friction

between roller and end plates that would

prematurely wear out the end plates.

The

DAR-vibrator can be operated intermittently without losing efficiency

or causing other difficulties

since the vibration stops immediately

after air pressure is cut.

Therefore, it is very useful in the concrete

industry to calculate accurate compaction times.

Lubrication

is required. One drop per five minutes is sufficient. In addition,

only filtered, clean air (40 µm filter is sufficient) should

be used.

Dirt will cause the roller to jump and dents or cracks in

the steel races will result.

Please

make sure that hydraulic oil ISO VG5 with 5 cSt/40°C is used.

Any other viscosity may cause the unit to clog

or reduce the vibrating

frequency and power.