|

The Powtek AIRBRATOR has a unique design that introduces pressurized air only where is needed to aid product flow without over fluidizing the material. It is widely used where powder and pellet products compact inside hoppers, silos and other containers causing bridging or arching that obstruct the container‘s discharge opening. .

|

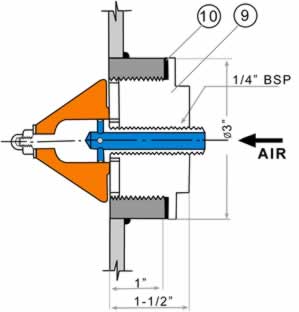

How it works Compressed air is introduced by the Airbrator into the container in a round pattern generating a thin layer of air between the bin wall and the product. Due to this air cushion, product friction against the wall is drastically reduced thus causing material to fall much easier. The white polymer cone is shaken by the compressed air generating a light vibration helping evacuate the material. When the nozzle is totally immersed in the product and not operating, product weight and the elasticity of the plastic cone keep the device against the wall preventing any product from entering the air line. |

Features Outstanding fluidization of the bin walls. Functions even with the presence of moisture in the air supply. Ease of installation Can be installed both |

|

TYPE "A" |

TYPE "B" |

1. Vibrating cone

2. Washer (Stainless Steel) 3. Cap Nut (Stainless Steel) 4. Injector core 5. Gasket 6. Pressure Washer 7. Nut and Locknut 8. Air inlet fitting 9. Hub 10. Gasket |

|

|

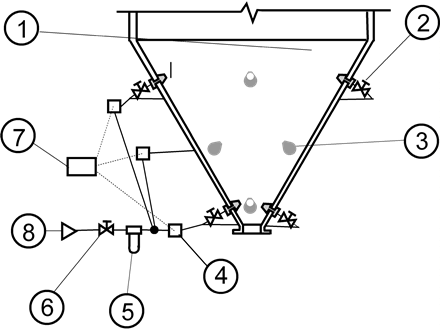

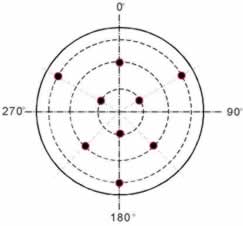

LAYOUT -ACCESSORIES |

LAYOUT- SIDE VIEW |

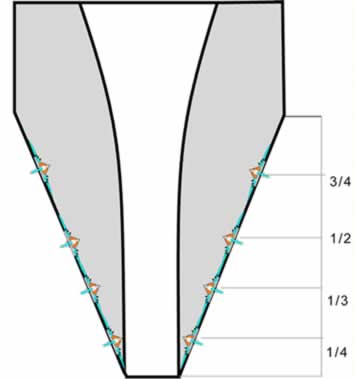

LAYOUT- BOTTOM VIEW |

|

|

|

Applications Airbrators excel with many difficult products like bentonite ash flour cement feldspar soda kaolin aluminum titanium dioxide. |